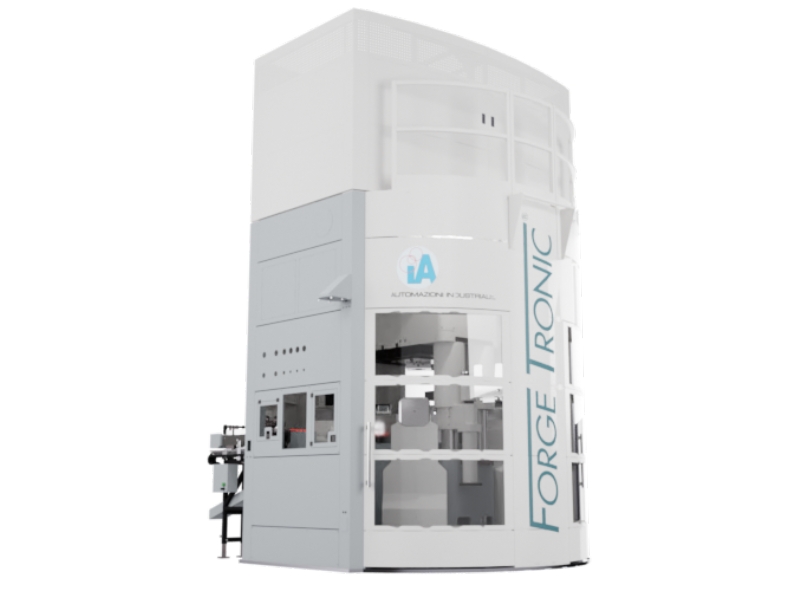

We turn the art of forging into forging technology

Productivity

It produces up to 6000 pcs/h, forging four parts at a time.

Setup time reduced by 50% compared to standard.

Setup time reduced by 50% compared to standard.

Usability

It is based on the CNC philosophy, in fact every parameter is adjustable in real-time. It is programmable offline via dedicated CAD-CAM.

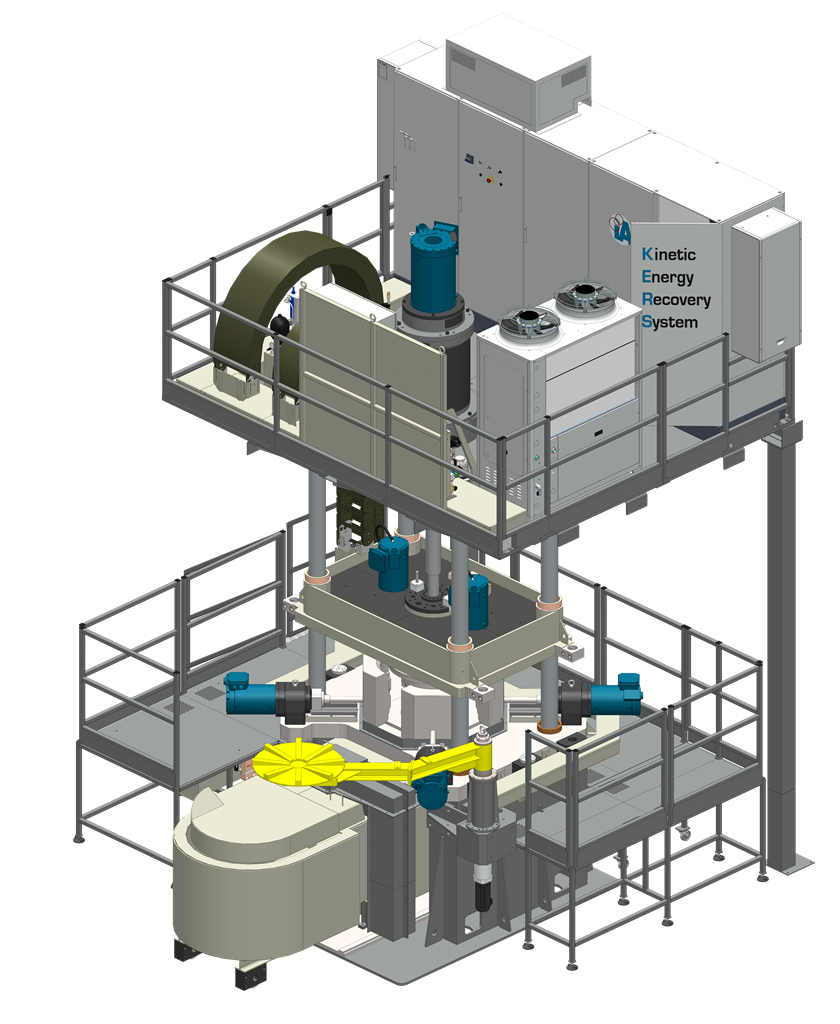

Saving

Lowest energy consumption in the industry (max. 35 kW/h). The integrated lubrication allows the life of the dies to be tripled. Rejects are reduced from 1.5% to 0.4%.

End product

High flexibility and wide range of products that can be forged. Burr-free forging ensures high product quality and a reduction of raw material used.

Our products

Did you know that we forge without burrs?

Forge Tronic

UNIQUE - ELECTRIC - GREEN